As the world we live in becomes more and more regulated, manufacturing companies must be especially aware of their compliance needs and have an adequate ERP solution to meet those needs.

Every manufacturing company needs to have some sort of tracking in place in its ERP system, but the extent to which tracking is required varies based on the type of manufacturing and the regulatory authorities in charge of that specific segment. For the companies that manufacture consumer products such as food products and pharmaceuticals and are regulated by the Food and Drug Administration (FDA), tracking and quality are extremely important and should be reflected in their ERP systems. The transportation industry, including both automobile and airplane manufacturers, has equally as high regulatory standards from the National Highway Traffic Safety Administraton (NHTSA) and the Federal Aviation Administration (FAA).

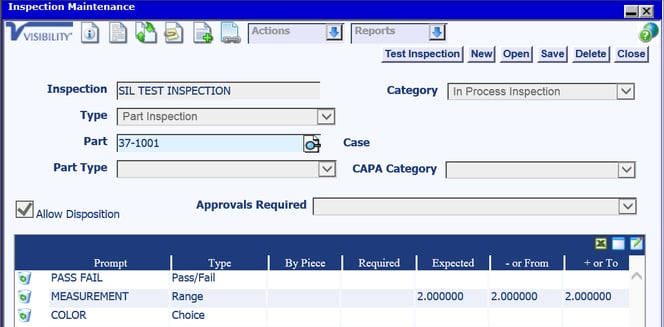

Quality Managment is an important regulatory compliance item, applications like those shown above allow companies to manage testing and inspection criteria for their purchased and manufactured items.

At Visibility, we focus on serving make-to-order manufacturers. Make-to-order manufacturers span many manufacturing segments, including aerospace and defense manufacturing, high tech and electronics manufacturing, and machinery manufacturing. Although most make-to-order products are not directly used by consumers, make-to-order manufacturers still need to make sure their ERP system has a robust compliance component. Here's why:

- Many of our make-to-order customers are government contractors in the aerospace and defense fields and therefore are held to extremely high regulatory standards.

- Many make-to-order machines will be sold to other manufacturing companies and operated by employees- if one of those employees is injured while using one of those machines, the make-to-order machine company is going to rely on its ERP systems’ compliance features to trace all the steps show that it was not at fault for the injury.

- Lastly, consumers are indirectly related to many make-to-order products as many make-to-order machines are used manufacture consumer goods such as the packaging and wrapping for consumer goods.

Here are the five most important compliance needs to look for when considering an ERP system:

- Traceability and Lot Serial Tracking

- Quality and Supply Chain Management

- Electronic Document Management

- Inventory Tracking

- Sarbanes Oxley Compliant

To read more about how Visibility is Sarbanes-Oxley compliant click here.