Industry Focus: Capital Equipment ERP

By: Scott Cranford

This is the fourth in our industry focus series in which we will highlight the customer successes in a specific industry or niche manufacturing segment. We’ll focus on the relevant capital equipment ERP functionality that an industry or market requires and how an ERP solution can address the unique needs of each of those industries. For our fourth edition, we thought we would focus on a bit of a broader segment, that being capital equipment. In particular, we’ll focus on custom capital equipment; machinery used in the production of other commodities.

This article should be of interest to any custom equipment manufacturing company; in particular make-to-order and engineer-to-order capital equipment. Converting, printing, injection molding, automated electronics assembly, laboratory automation; just a small sampling of capital equipment manufacturing companies.

The profile of these companies is quite similar to others that we have highlighted in this series. As an ERP software company, we’ll specifically focus on the some of the key functions of these organizations. Functions that support the high dollar, low volume production model. Functions to assist with the engineering intensive nature, the emphasis on accurate and robust estimating and the ability to monitor and manage all activities of building capital equipment in a project.

So what are some of the key requirements of capital equipment manufacturing? We’ll focus on five functional areas that are of critical importance.

- Quotation Processing. Capital equipment manufacturers require strong CRM and front-end quoting solutions. Often times, companies manage job quoting and estimating in offline spreadsheets. Those can now be replaced by native estimating functionality to support pricing, costing, margin, markup, version control, change orders, job profitability, numerous cost buckets and varying markup percentages by cost bucket, labor or material.

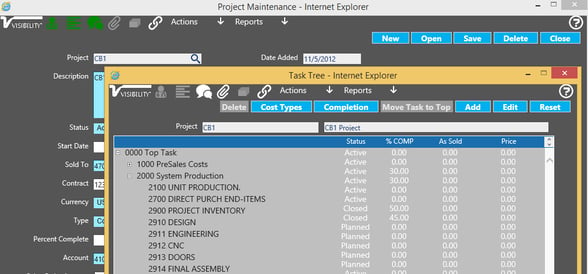

- The solution must be rooted in Engineer to Order (ETO); meaning that from an engineering perspective there must be robust support for project management, deep bills of material, engineering change control, Engineering Product Data Management (EPDM), document management, engineering workflow, revision control and material traceability.

- Production Scheduling. These types of companies might also look for solutions to help them with improved production scheduling to ensure that the right combination of people, raw materials, machines and skills are available when needed for the specific machine in production. This aspect is also vital as companies may be involved in concurrent engineering; actively producing sections of the machine while still completing engineering design work on others. Having an ERP solution that supports the ability to release sections of the job or project by sections can produce some significant efficiency gains.

- Material Control. Running MRP by project or job, multi-level order pegging, purchasing specific to project tasks and project inventories, location control and warehouse management functionality are but a few examples of what custom capital equipment manufacturers are looking for in an integrated ERP solution.

- Project Management and Accounting. Capital equipment companies often are managing long projects with their customers. To support that, built-in functions that support these long term engagements are key. ERP systems with this type of industry focus should deliver excellence in contract management, revenue recognition, progress payments, project performance, earned value, estimate at / to completion and project accounting dashboards and key performance indicators.

These are five areas of focus for this type of custom capital equipment company. As part of an overall ERP solution, they make up an important set of functions and pre-requisites for an ERP system implementation.

We hope you have enjoyed reading our fourth of many industry focus articles. Subscribe to our posts so that you will receive notifications on future industries!

To learn more about Visibility, please visit our ERP solutions home page. Or to have a Visibility representative contact you, click on the button below and simply provide us with some basic contact details and we will follow up shortly.